(P+3/8-050-FSL) Panther Full Skip Chisel Chain 3/8 .050[1.3mm] [ONLY IN 96 and 108 drive links]

Part Number P+3/8-050-FSL

$ 0.54

(P+3/8-050-FSL) Panther Full Skip Chisel Chain 3/8 .050[1.3mm] [ONLY IN 96 and 108 drive links] quantity

Add to

(P+3/8-050-LG) Panther Plus Chisel Guarded 3/8 .050[1.3mm]

Part Number P+3/8-050-LG

$ 0.66

(P+3/8-050-LG) Panther Plus Chisel Guarded 3/8 .050[1.3mm] quantity

With this chain if you are seeing this message we only have loops in certain sizes and no means to make others. Please choose another chain.

Add to

(P+3/8-058-LG) Panther Plus Chisel Guarded 3/8 .058[1.5mm]

Part Number P+3/8-058-LG

$ 0.62

(P+3/8-058-LG) Panther Plus Chisel Guarded 3/8 .058[1.5mm] quantity

Add to

(P+3/8-063-FSL) Panther Full Skip Chisel Chain 3/8 .063[1.6mm] [ONLY 72|92]

Part Number P+3/8-063-FSL

$ 0.54

(P+3/8-063-FSL) Panther Full Skip Chisel Chain 3/8 .063[1.6mm] [ONLY 72|92] quantity

Sorry if the website does not allow you to buy the chain length you require it means we don’t have it available right now please choose another chain.

Add to

(P+3/8-063-LG) Panther Plus Chisel Guarded 3/8 .063[1.6mm]

Part Number P+3/8-063-LG

$ 0.54

(P+3/8-063-LG) Panther Plus Chisel Guarded 3/8 .063[1.6mm] quantity

With this chain if you are seeing this message we can’t do the chain length you require – please pick another chain. If you need more info Whatsapp on

Add to

(P+3/8LP-050-FSL) Panther Lo Pro Full Skip Chisel Chain 3/8 Lo Pro .050[1.3mm] Only in 60/72/84

Part Number P+3/8LP-050-FSL

$ 0.62

(P+3/8LP-050-FSL) Panther Lo Pro Full Skip Chisel Chain 3/8 Lo Pro .050[1.3mm] Only in 60/72/84 quantity

Only in 60/72/84 link configurations – no other options available at the moment.

Add to

(P+3/8LP-050-FSR) Panther Lo Pro Full Skip Ripping Chain 3/8 Lo Pro .050[1.3mm]

Part Number P+3/8LP-050-FSR

$ 0.62

(P+3/8LP-050-FSR) Panther Lo Pro Full Skip Ripping Chain 3/8 Lo Pro .050[1.3mm] quantity

Add to

(P+3/8LP-050-L) Panther Plus Chisel 3/8 Lo Pro .050[1.3mm] [ONLY 45|52 in stock at present]

Part Number P+3/8LP-050-L

$ 0.54

(P+3/8LP-050-L) Panther Plus Chisel 3/8 Lo Pro .050[1.3mm] [ONLY 45|52 in stock at present] quantity

Hi – we don’t have this chain as a stock item and for this chain we are unable to make any chain lengths other than what the website lets you order so if seeing this message please pick another chain. We will have more of this chain around April/May 2024

Add to

(P+3/8LP-050-LG) Panther Plus Lo Pro Full Chisel Chain [Guarded Version] 3/8 Lo Pro .050[1.3mm]

Part Number P+3/8LP-050-LG

$ 0.54

(P+3/8LP-050-LG) Panther Plus Lo Pro Full Chisel Chain [Guarded Version] 3/8 Lo Pro .050[1.3mm] quantity

Add to

(P+325-050-LG) Panther Plus Chisel Guarded .325 .050[1.3mm]

Part Number P+325-050-LG

$ 0.62

(P+325-050-LG) Panther Plus Chisel Guarded .325 .050[1.3mm] quantity

Add to

(P+325-058-LG) Panther Plus Chisel Guarded .325 .058[1.5mm]

Part Number P+325-058-LG

$ 0.54

(P+325-058-LG) Panther Plus Chisel Guarded .325 .058[1.5mm] quantity

Longer term the Panther range of chains will be narrowed down to a smaller range all of which will be the unguarded versions (which happen to be the most popular). If this message is popping up please choose another chain as we don’t have it in the length you want.

Add to

(P+325-063-LG) Panther Plus Chisel Guarded .325 .063[1.6mm]

Part Number P+325-063-LG

$ 0.62

(P+325-063-LG) Panther Plus Chisel Guarded .325 .063[1.6mm] quantity

Add to

(P+404-FSR) Full Skip Ripping Chain .404 .063[1.6mm] [ONLY 148|180|196|222]

Part Number P+404-FSR

$ 0.81

(P+404-FSR) Full Skip Ripping Chain .404 .063[1.6mm] [ONLY 148|180|196|222] quantity

If you are seeing this we cannot make the chain length you require at this time likely we can from Sept 2014 onwards]

Add to

(P+404-HSR) Hyper Skip Ripping Chain .404 .063[1.6mm]

Part Number P+404-HSR

$ 0.81

(P+404-HSR) Hyper Skip Ripping Chain .404 .063[1.6mm] quantity

Add to

(P+404-R) Ripping .404 .063[1.6mm]

Part Number P+404-R

$ 0.81

(P+404-R) Ripping .404 .063[1.6mm] quantity

Add to

(P-1/4-043-MFS) Panther Mini Chain [Unguarded] Full Skip 1/4 .043 [1.1mm] [ONLY Available 80|88|100]

Part Number P-1/4-043-MFS

$ 0.46

(P-1/4-043-MFS) Panther Mini Chain [Unguarded] Full Skip 1/4 .043 [1.1mm] [ONLY Available 80|88|100] quantity

Add to

(P-1/4-043-MG) Panther Mini Chain [Guarded Version] 1/4 .043 [1.1mm]

Part Number P-1/4-043-MG

$ 0.31

(P-1/4-043-MG) Panther Mini Chain [Guarded Version] 1/4 .043 [1.1mm] quantity

Add to

(P-1/4-050-SC) Panther Semi Chisel 1/4 .050[1.3mm]

Part Number P-1/4-050-SC

$ 0.50

(P-1/4-050-SC) Panther Semi Chisel 1/4 .050[1.3mm] quantity

If this message is popping up we can’t do this chain length until end June 2024

Add to

(P-3/8-050-FSLG) Panther Full Skip Chisel Chain [Guarded] 3/8 .050[1.3mm]

Part Number P-3/8-050-FSLG

$ 0.54

(P-3/8-050-FSLG) Panther Full Skip Chisel Chain [Guarded] 3/8 .050[1.3mm] quantity

Add to

(P-3/8-050-FSR) Panther Full Skip Ripping Chain 3/8 .050[1.3mm]

Part Number P-3/8-050-FSR

$ 0.54

(P-3/8-050-FSR) Panther Full Skip Ripping Chain 3/8 .050[1.3mm] quantity

Add to

(P-3/8-058-FSR) Panther Full Skip Ripping Chain 3/8 .058[1.5mm]

Part Number P-3/8-058-FSR

$ 0.54

(P-3/8-058-FSR) Panther Full Skip Ripping Chain 3/8 .058[1.5mm] quantity

Add to

(P-3/8-058-R) Panther Ripping Chain 3/8 .058[1.5mm]

Part Number P-3/8-058-R

$ 0.50

(P-3/8-058-R) Panther Ripping Chain 3/8 .058[1.5mm] quantity

Add to

(P-3/8-063-FSLG) Panther Full Skip Chisel Chain [Guarded] 3/8 .063[1.6mm][ONLY In 72|84|92|105|115]

Part Number P-3/8-063-FSLG

$ 0.54

(P-3/8-063-FSLG) Panther Full Skip Chisel Chain [Guarded] 3/8 .063[1.6mm][ONLY In 72|84|92|105|115] quantity

Add to

(P-3/8-063-FSR) Panther Full Skip Ripping Chain 3/8 .063[1.6mm]

Part Number P-3/8-063-FSR

$ 0.54

(P-3/8-063-FSR) Panther Full Skip Ripping Chain 3/8 .063[1.6mm] quantity

If the chain you require is not being allowed to be purchased then we don’t have in stock from some months please choose another chain.

Add to

(P-3/8-063-R) Panther Ripping Chain 3/8 .063[1.6mm]

Part Number P-3/8-063-R

$ 0.50

(P-3/8-063-R) Panther Ripping Chain 3/8 .063[1.6mm] quantity

Add to

(P-3/8LP-050-FSR) Panther Lo Pro Full Skip Ripping Chain 3/8 Lo Pro .050[1.3mm]

Part Number P-3/8LP-050-FSR

$ 0.58

(P-3/8LP-050-FSR) Panther Lo Pro Full Skip Ripping Chain 3/8 Lo Pro .050[1.3mm] quantity

Add to

(P-3/8LP-050-R) Panther Lo Pro Ripping Chain 3/8 Lo Pro .050[1.3mm]

Part Number P-3/8LP-050-R

$ 0.50

(P-3/8LP-050-R) Panther Lo Pro Ripping Chain 3/8 Lo Pro .050[1.3mm] quantity

Add to

(P-325-043-G) Panther .325 .043[1.1mm][26,41,45,46,51,59,64 drive links only]

Part Number P-325-043-G

$ 0.46

(P-325-043-G) Panther .325 .043[1.1mm][26,41,45,46,51,59,64 drive links only] quantity

Add to

(P-325-050-FSR) Panther Full Skip Ripping Chain .325 .050[1.3mm]

Part Number P-325-050-FSR

$ 0.54

(P-325-050-FSR) Panther Full Skip Ripping Chain .325 .050[1.3mm] quantity

Add to

(P-325-050-R) Panther Ripping Chain .325 .050[1.3mm]

Part Number P-325-050-R

$ 0.42Out of Stock

(P-325-058-FSR) Panther Full Skip Ripping Chain .325 .058[1.5mm]

Part Number P-325-058-FSR

$ 0.54

(P-325-058-FSR) Panther Full Skip Ripping Chain .325 .058[1.5mm] quantity

Add to

(P-325-058-R) Panther Ripping Chain .325 .058[1.5mm]

Part Number P-325-058-R

$ 0.42

(P-325-058-R) Panther Ripping Chain .325 .058[1.5mm] quantity

Add to

(P-325-063-FSR) Panther Full Skip Ripping Chain .325 .063[1.6mm]

Part Number P-325-063-FSR

$ 0.54

(P-325-063-FSR) Panther Full Skip Ripping Chain .325 .063[1.6mm] quantity

Add to

(P-325-063-R) Panther Ripping Chain .325 .063[1.6mm]

Part Number P-325-063-R

$ 0.42

(P-325-063-R) Panther Ripping Chain .325 .063[1.6mm] quantity

Add to

(P-404-FSR) Full Skip Ripping Chain .404 .063[1.6mm]

Part Number P-404-FSR

$ 0.73

(P-404-FSR) Full Skip Ripping Chain .404 .063[1.6mm] quantity

Add to

(P-404-HSR) Hyper Skip Ripping Chain .404 .063[1.6mm]

Part Number P-404-HSR

$ 0.73

(P-404-HSR) Hyper Skip Ripping Chain .404 .063[1.6mm] quantity

Add to

(P-404-R) Ripping .404 .063[1.6mm]

Part Number P-404-R

$ 0.73

(P-404-R) Ripping .404 .063[1.6mm] quantity

Add to

(PP-3/8LP-050-L) Panther Platinum Chisel Unguarded 3/8 Lo Pro .050[1.3mm]

Part Number PP-3/8LP-050-L

$ 0.54

(PP-3/8LP-050-L) Panther Platinum Chisel Unguarded 3/8 Lo Pro .050[1.3mm] quantity

Hi – sorry we don’t have this chain length as a stock item right now. Please choose another chain.

Add to

(PP-3/8LP-050-LG) Panther Platinum Chisel Guarded 3/8 Lo Pro .050[1.3mm] ONLY 50/55 Drive Links

Part Number PP-3/8LP-050-LG

$ 0.54

(PP-3/8LP-050-LG) Panther Platinum Chisel Guarded 3/8 Lo Pro .050[1.3mm] ONLY 50/55 Drive Links quantity

Hi – sorry we don’t have this chain length as a stock item right now. Please choose another chain.

Add to

20LGX Oregon Pro Chisel .325 .050[1.3mm]

Part Number 20LGX

$ 0.58

20LGX Oregon Pro Chisel .325 .050[1.3mm] quantity

Add to

20LPX Oregon Chisel .325 .050[1.3mm]

Part Number 20LPX

$ 0.58Out of Stock

21BPX Oregon Micro Chisel .325 .058[1.5mm]

Part Number 21BPX

$ 0.58

21BPX Oregon Micro Chisel .325 .058[1.5mm] quantity

Add to

21LGX Oregon Oregon Pro Chisel .325 .058[1.5mm]

Part Number 21LGX

$ 0.58

21LGX Oregon Oregon Pro Chisel .325 .058[1.5mm] quantity

Add to

21LPX Oregon Full Chisel .325 .058[1.5mm]

Part Number 21LPX

$ 0.58

21LPX Oregon Full Chisel .325 .058[1.5mm] quantity

Add to

22BPX Oregon Micro Chisel .325 .063[1.6mm]

Part Number 22BPX

$ 0.58

22BPX Oregon Micro Chisel .325 .063[1.6mm] quantity

Add to

22LGX Oregon Oregon Pro Chisel .325 .063[1.6mm]

Part Number 22LGX

$ 0.58

22LGX Oregon Oregon Pro Chisel .325 .063[1.6mm] quantity

Add to

22LPX Oregon Chisel .325 .063[1.6mm]

Part Number 22LPX

$ 0.58

22LPX Oregon Chisel .325 .063[1.6mm] quantity

Add to

24AP Oregon Mini Chain [Guarded] 1/4 .043 [1.1mm] [ONLY 28,56,57,64,65,72 Available]

Part Number 24AP

$ 0.46

24AP Oregon Mini Chain [Guarded] 1/4 .043 [1.1mm] [ONLY 28,56,57,64,65,72 Available] quantity

If the website is not allowing you to choose the chain loop you require then it is unavailable – this chain is only available in loops of 28,56,57,64,65,72 at the moment.

Add to

27R Oregon Ripping .404 .063[1.6mm] [Long Term Out of Stock Instead Use P-404-R]

Part Number 27R

$ 0.77Out of Stock

27RA Oregon Full Skip Ripping Chain .404 .063[1.6mm]

Part Number 27RA

$ 0.77

27RA Oregon Full Skip Ripping Chain .404 .063[1.6mm] quantity

Add to

27RX Oregon Hyper Skip Ripping Chain .404 .063[1.6mm]

Part Number 27RX

$ 0.77

27RX Oregon Hyper Skip Ripping Chain .404 .063[1.6mm] quantity

The chain is not available in the size you requested. Please select Panther P-404-HSR chain. If no luck then please call or whatsapp +447752 145001 (whatsapp is generally the faster option).

Add to

3132-36RH Stihl Rapid Hexa [Square Chisel] 3/8 .063[1.6mm]

Part Number 31320000

$ 1.04

3132-36RH Stihl Rapid Hexa [Square Chisel] 3/8 .063[1.6mm] quantity

Add to

3610-61PMM3 Stihl Narrow Kerf 3/8 Lo Pro .043 [1.1mm]

Part Number 36100000

$ 0.69

3610-61PMM3 Stihl Narrow Kerf 3/8 Lo Pro .043 [1.1mm] quantity

Add to

3614-63PMX Stihl PMX Ripping Chain 3/8 Lo Pro .050[1.3mm]

Part Number 36140000

$ 0.73

3614-63PMX Stihl PMX Ripping Chain 3/8 Lo Pro .050[1.3mm] quantity

Add to

3616-63PS3 Stihl Lo Pro Chisel Guarded] 3/8 Lo Pro .050[1.3mm]

Part Number 36160000

$ 0.85

3616-63PS3 Stihl Lo Pro Chisel Guarded] 3/8 Lo Pro .050[1.3mm] quantity

Add to

3617-63PS Stihl 3/8 Lo Pro .050[1.3mm] Chisel Unguarded

Part Number 36170000

$ 0.93

3617-63PS Stihl 3/8 Lo Pro .050[1.3mm] Chisel Unguarded quantity

This chain has now been discontinued by Stihl – if you are seeing this we cannot make the chain length you require. The only unguarded option in chisel 3/8 lo pro .050[1.3mm] is now the Panther versions which we will look to increase availability of during 2023/2024 and can be found by clicking here.

Add to

3621-36RS Stihl Rapid Super [Chisel] 3/8 .063[1.6mm]

Part Number 36210000

$ 0.85

3621-36RS Stihl Rapid Super [Chisel] 3/8 .063[1.6mm] quantity

Add to

3622-35RS Stihl Chisel 3/8 .058[1.5mm]

Part Number 36220000

$ 0.85

3622-35RS Stihl Chisel 3/8 .058[1.5mm] quantity

Add to

3636-63PM3 Stihl Lo Pro Micro Chisel 3/8 Lo Pro .050[1.3mm]

Part Number 36360000

$ 0.71

3636-63PM3 Stihl Lo Pro Micro Chisel 3/8 Lo Pro .050[1.3mm] quantity

Add to

3637-26RS-D Stihl Chisel .325 .050[1.3mm] Only Available in 62|66|72|80

Part Number 36370000

$ 0.77

3637-26RS-D Stihl Chisel .325 .050[1.3mm] Only Available in 62|66|72|80 quantity

This chain has now been discontinued by Stihl – if you are seeing this we cannot make the chain length you require please choose another option.

Add to

3638-25RS Stihl Chisel .325 .058[1.5mm]

Part Number 36380000

$ 0.71

3638-25RS Stihl Chisel .325 .058[1.5mm] quantity

Add to

3639-26RS Stihl Chisel .325 .063[1.6mm]

Part Number 36390000

$ 0.71

3639-26RS Stihl Chisel .325 .063[1.6mm] quantity

Add to

3651-35RM Stihl Micro Chisel 3/8 .058[1.5mm]

Part Number 36510000

$ 0.85

3651-35RM Stihl Micro Chisel 3/8 .058[1.5mm] quantity

Add to

3652-36RM Stihl Micro Chisel 3/8 .063[1.6mm]

Part Number 36520000

$ 0.85

3652-36RM Stihl Micro Chisel 3/8 .063[1.6mm] quantity

Add to

3653-36RMX Stihl Ripping 3/8 .063[1.6mm]

Part Number 36530000

$ 0.85

3653-36RMX Stihl Ripping 3/8 .063[1.6mm] quantity

Add to

3661-13RMS Stihl Carving Micro Chisel 1/4 .050[1.3mm]

Part Number 36610000

$ 0.75

3661-13RMS Stihl Carving Micro Chisel 1/4 .050[1.3mm] quantity

Add to

3668-46RM Stihl Micro Chisel .404 .063[1.6mm]

Part Number 36680000

$ 0.93

3668-46RM Stihl Micro Chisel .404 .063[1.6mm] quantity

Add to

3670-71PM3 Stihl Micro Chisel 1/4 .043[1.1mm]

Part Number 36700000

$ 0.56

3670-71PM3 Stihl Micro Chisel 1/4 .043[1.1mm] quantity

Add to

3685-25RM Stihl Micro Chisel .325 .058[1.5mm]

Part Number 36850000

$ 0.77

3685-25RM Stihl Micro Chisel .325 .058[1.5mm] quantity

Add to

3686-26RM Stihl Micro Chisel .325 .063[1.6mm]

Part Number 36860000

$ 0.77

3686-26RM Stihl Micro Chisel .325 .063[1.6mm] quantity

Add to

3687-23RM3 Stihl Micro Chisel Comfort .325 .050[1.3mm] – To Be Discontinued in favour of 3693-23RM

Part Number 36870000

$ 0.71Original price was: $0.71. $ 0.58Current price is: $0.58.

3687-23RM3 Stihl Micro Chisel Comfort .325 .050[1.3mm] - To Be Discontinued in favour of 3693-23RM quantity

Add to

3689-26RM3 Stihl Micro Chisel .325 .063[1.6mm]

Part Number 36890000

$ 0.71

3689-26RM3 Stihl Micro Chisel .325 .063[1.6mm] quantity

Add to

3690-23RS PRO NEW Stihl Rapid Super Chisel [Narrow Kerf] .325 .050[1.3mm]

Part Number 36900000

$ 0.71

3690-23RS PRO NEW Stihl Rapid Super Chisel [Narrow Kerf] .325 .050[1.3mm] quantity

Add to

3693-23RM PRO NEW Stihl Rapid Micro Chisel PRO [Narrow Kerf] .325 .050[1.3mm]

Part Number 36930000

$ 0.71

3693-23RM PRO NEW Stihl Rapid Micro Chisel PRO [Narrow Kerf] .325 .050[1.3mm] quantity

Add to

3699-61PS3 Stihl Narrow Kerf Full Chisel 3/8 Lo Pro .043[1.1mm]

Part Number 36990000

$ 0.85

3699-61PS3 Stihl Narrow Kerf Full Chisel 3/8 Lo Pro .043[1.1mm] quantity

Add to

3946-46RS Stihl Chisel .404 .063[1.6mm]

Part Number 39460000

$ 0.93

3946-46RS Stihl Chisel .404 .063[1.6mm] quantity

Add to

3958-46RCX Stihl Ripping .404 .063[1.6mm]

Part Number 39580000

$ 0.93

3958-46RCX Stihl Ripping .404 .063[1.6mm] quantity

Add to

59ACL Oregon Chipper .404 .063[1.6mm]

Part Number 59ACL

$ 0.77

59ACL Oregon Chipper .404 .063[1.6mm] quantity

Add to

59L Oregon Full Chisel .404 .063[1.6mm]

Part Number 59L

$ 0.77

59L Oregon Full Chisel .404 .063[1.6mm] quantity

Add to

68JX Oregon Full Skip Chisel .404 .063[1.6mm]

Part Number 68JX

$ 0.93

68JX Oregon Full Skip Chisel .404 .063[1.6mm] quantity

Add to

72DPX Oregon Semi Chisel 3/8 .050[1.3mm]

Part Number 72DPX

$ 0.66

72DPX Oregon Semi Chisel 3/8 .050[1.3mm] quantity

Add to

72JGX Oregon Full Skip Chisel Chain 3/8 .050[1.3mm]

Part Number 72JGX

$ 0.77Out of Stock

72LPX Oregon Chisel 3/8 .050[1.3mm]

Part Number 72LPX

$ 0.66

72LPX Oregon Chisel 3/8 .050[1.3mm] quantity

Add to

73DPX Oregon Semi Chisel 3/8 .058[1.5mm]

Part Number 73DPX

$ 0.66

73DPX Oregon Semi Chisel 3/8 .058[1.5mm] quantity

Add to

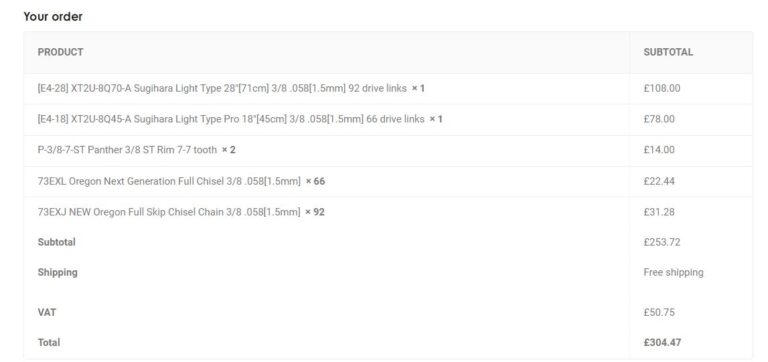

73EXJ NEW Oregon Full Skip Chisel Chain 3/8 .058[1.5mm]

Part Number 73EXJ

$ 0.73

73EXJ NEW Oregon Full Skip Chisel Chain 3/8 .058[1.5mm] quantity

Hi – we don’t have this chain as a stock item but we can easily add it just for you 🙂 whatsapp us on +447752145001 or call and let us know what length of chain you are after.

Add to

73EXL Oregon Next Generation Full Chisel 3/8 .058[1.5mm]

Part Number 73EXL

$ 0.66

73EXL Oregon Next Generation Full Chisel 3/8 .058[1.5mm] quantity

Add to

73LGX Oregon Full Chisel 3/8 .058[1.5mm]

Part Number 73LGX

$ 0.66Out of Stock

73RD Oregon Ripping 3/8 .058[1.5mm]

Part Number 73RD

$ 0.66

73RD Oregon Ripping 3/8 .058[1.5mm] quantity

Add to

75CJ Oregon Square Ground Full Skip Chisel 3/8 .063[1.6mm]

Part Number 75CJ

$ 0.85

75CJ Oregon Square Ground Full Skip Chisel 3/8 .063[1.6mm] quantity

Add to

75CL Oregon Square Ground Chisel 3/8 .063[1.6mm]

Part Number 75CL

$ 0.85

75CL Oregon Square Ground Chisel 3/8 .063[1.6mm] quantity

Hi – sorry we don’t have this chain length as a stock item right now but whatsapp us on +44 (0)7752 145 001 and we shall make it for you!

Add to

75DPX Oregon Semi Chisel 3/8 .063[1.6mm]

Part Number 75DPX

$ 0.66

75DPX Oregon Semi Chisel 3/8 .063[1.6mm] quantity

Add to

75EXJ Oregon Full Skip Chisel Chain 3/8 .063[1.6mm]

Part Number 75EXJ

$ 0.73

75EXJ Oregon Full Skip Chisel Chain 3/8 .063[1.6mm] quantity

Add to

75EXL Oregon Next Generation Full Chisel 3/8 .063[1.6mm]

Part Number 75EXL

$ 0.66

75EXL Oregon Next Generation Full Chisel 3/8 .063[1.6mm] quantity

Add to

75RD Oregon Ripping 3/8 .063[1.6mm]

Part Number 75RD

$ 0.66

75RD Oregon Ripping 3/8 .063[1.6mm] quantity

Add to

80TXL Oregon Speedcut Nano .325 .043[1.1mm] [46,51,59,64 drive links only]

Part Number 80TXL

$ 0.66

80TXL Oregon Speedcut Nano .325 .043[1.1mm] [46,51,59,64 drive links only] quantity

With this chain if you are seeing this message we can’t do the chain length you require – please pick another chain. If you need more info Whatsapp on

Add to

90PX Oregon Narrow Kerf 3/8 Lo Pro .043[1.1mm]

Part Number 90PX

$ 0.58

90PX Oregon Narrow Kerf 3/8 Lo Pro .043[1.1mm] quantity

Add to

91PX Oregon Lo Pro Hobby 3/8 Lo Pro .050[1.3mm]

Part Number 91PX

$ 0.58

91PX Oregon Lo Pro Hobby 3/8 Lo Pro .050[1.3mm] quantity

Add to

91R Oregon Ripping Chain 3/8 Lo Pro .050[1.3mm]

Part Number 91R

$ 0.58

91R Oregon Ripping Chain 3/8 Lo Pro .050[1.3mm] quantity

Add to

91VXL Oregon Lo Pro Rapid 3/8 Lo Pro .050[1.3mm]

Part Number 91VXL

$ 0.58

91VXL Oregon Lo Pro Rapid 3/8 Lo Pro .050[1.3mm] quantity

Add to

95TXL Oregon Lo Pro .325 .050[1.3mm]

Part Number 95TXL

$ 0.58

95TXL Oregon Lo Pro .325 .050[1.3mm] quantity

Add to

A4SMB Sugihara Mini Chain 1/4 .042[1.1mm] Sugi Mini Bars ONLY

Part Number A4SMB

$ 0.39

A4SMB Sugihara Mini Chain 1/4 .042[1.1mm] Sugi Mini Bars ONLY quantity

Add to

G-3/8-050 Granberg Ripping 3/8 .050 [ONLY 72/84/91]

Part Number G-3/8-050

$ 1.16

G-3/8-050 Granberg Ripping 3/8 .050 [ONLY 72/84/91] quantity

This chain has now been discontinued – if you are seeing this we cannot make the chain length you require please pick another option.

Add to

G-3/8-058 Granberg Ripping 3/8 .058 [ONLY 64/72/80/92]

Part Number G-3/8-058

$ 1.16Out of Stock

G-3/8-LP Granberg Ripping 3/8 Lo Pro .050

Part Number G-3/8-LP

$ 1.16Out of Stock

G-325-050 Granberg Ripping .325 .050 [ONLY 56/64/66/72]

Part Number G-325-050

$ 1.08

G-325-050 Granberg Ripping .325 .050 [ONLY 56/64/66/72] quantity

This chain has now been discontinued – if you are seeing this we cannot make the chain length you require please pick another option.

Add to

G-325-058 Granberg Ripping .325 .058 [ONLY in 64|72|80|92]

Part Number G-325-058

$ 1.08

G-325-058 Granberg Ripping .325 .058 [ONLY in 64|72|80|92] quantity

Add to

M21LPX Oregon Chisel Multicut .325 .058[1.5mm]

Part Number M21LPX

$ 0.77

M21LPX Oregon Chisel Multicut .325 .058[1.5mm] quantity

Add to

M22LPX Oregon Chisel Multicut .325 .063[1.6mm][ONLY in 67 Drive Links]

Part Number M22LPX

$ 0.46

M22LPX Oregon Chisel Multicut .325 .063[1.6mm][ONLY in 67 Drive Links] quantity

Add to

M73LPX Oregon Chisel Multicut 3/8 .058[1.5mm]

Part Number M73LPX

$ 0.77

M73LPX Oregon Chisel Multicut 3/8 .058[1.5mm] quantity

Add to

M75LPX Oregon Chisel DuraCut 3/8 .063[1.6mm]

Part Number M75LPX

$ 0.77

M75LPX Oregon Chisel DuraCut 3/8 .063[1.6mm] quantity

Add to

M91VXL Oregon Lo Pro Multicut 3/8 Lo Pro .050[1.3mm]

Part Number M91VXL

$ 0.77

M91VXL Oregon Lo Pro Multicut 3/8 Lo Pro .050[1.3mm] quantity

Add to

M95VPX Oregon Lo Pro Multicut .325 .050[1.3mm]

Part Number M95VPX

$ 0.77

M95VPX Oregon Lo Pro Multicut .325 .050[1.3mm] quantity

Add to

PMC Panther Mini Chain [Unguarded] 1/4 .043 [1.1mm]

Part Number PMC-1/4-043

$ 0.46

PMC Panther Mini Chain [Unguarded] 1/4 .043 [1.1mm] quantity

If the website does not allow you to buy this length chain then it is not available right now please choose another chain.

Add to

SP21G Husqvarna Speedcut Nano .325 .043[1.1mm] [46, 51, 59, 64 drive links only]

Part Number 5939141

$ 0.81

SP21G Husqvarna Speedcut Nano .325 .043[1.1mm] [46, 51, 59, 64 drive links only] quantity

Add to

X-Cut C85 Husqvarna Full Chisel 3/8 .058[1.5mm]

Part Number 5816266

$ 0.85

X-Cut C85 Husqvarna Full Chisel 3/8 .058[1.5mm] quantity

Add to

X-Cut S93G Husqvarna 3/8 Lo Pro .050[1.3mm]

Part Number 5854042

$ 0.69

X-Cut S93G Husqvarna 3/8 Lo Pro .050[1.3mm] quantity

Add to

X-Cut SP33G Husqvarna [Quick Cut] .325 .050[1.3mm]

Part Number 5816431

$ 0.69

X-Cut SP33G Husqvarna [Quick Cut] .325 .050[1.3mm] quantity

Add to

text or whatsapp us

text or whatsapp us  orders@chainsawbars.co.uk

orders@chainsawbars.co.uk

sign me up

sign me up basket

basket