.

Chainsaw ripping chain comes in several different sizes so please select your chain from the options below:

.

.404 .063 Ripping Chains

3/8 Ripping Chains

.325 Ripping Chains

3/8 lo pro Ripping Chains

.

.

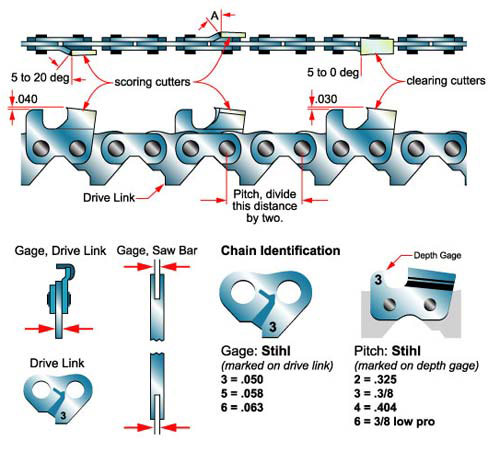

Ripping chain is chainsaw chain designed specifically for cutting with the grain. Ripping chain is always micro chisel or semi chisel chain which features a re configured cutting angle of 10 degrees.

.

With Oregon and Stihl ripping chain this is the only difference – the chain is not made differently or any different from ‘normal’ chain. Only the cutting angle is different.

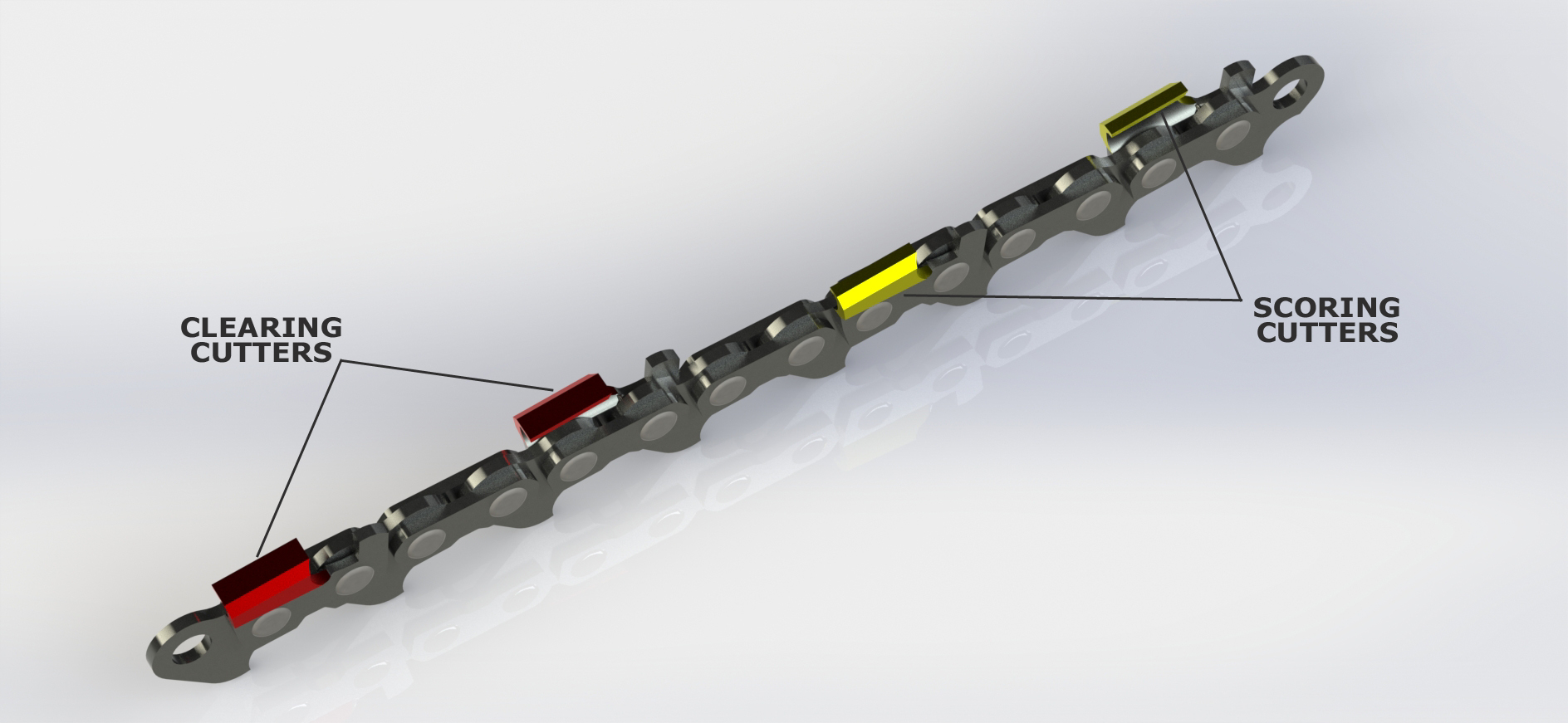

Granberg ripping chain has been modified further – this configuration features x2 scoring cutters followed by x2 clearing cutters. The easiest way to sharpen this is by making all the cutters 10 degrees however if you wish you can sharpen the scoring cutters to 20 degrees and the clearing cutters to 5 degrees.

Please bear in mind this process is carried out manually on a grinding machine at the factory and so some of the scoring cutters can become hardened in the process. This makes them very hard to sharpen using a round file and some sort of grinder may be required.

.

Idenitfy Parts Of The Chain

.

You need Ripping Chain to work with a chainsaw mill. It is dangerous to use ripping chain for ordinary cross cutting purposes as kick back could be more violent.

.

FAQS on Ripping Chain

Can I simply adapt my existing chain to become a ‘ripping chain’.

Yes you can but only if it is of the chisel or micro chisel variety. If you are not sure what type of chain you have then first job is to identify it. You can ID exactly which chain you have using our Essential Info pages here and the Chain ID table found here.

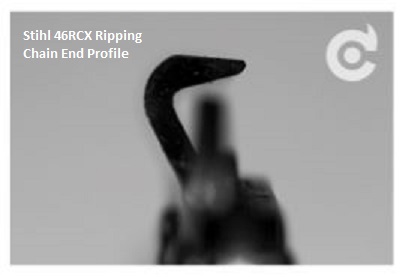

Now you know what make and size chain you have look down the chain at the outer profile – check the pictures below of the Oregon 27R and Stihl 46RCX). Does your chain profile look similar to this? If so it is micro or semi chisel chain. If you have semi or micro chisel chain you can alter the angle from 30 degrees to 10 degrees.

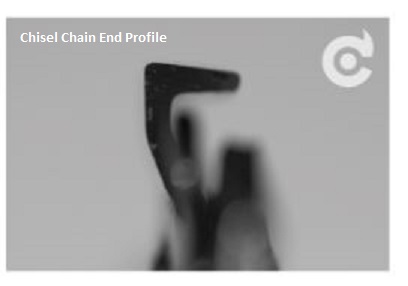

Chisel chain has a very right angled appearance while micro or semi chisel chain as a more rounded appearance. Remember chisel chain is no use to convert into ripping chain. Check the end profile and confirm if you have chisel chain – it will look something like the below picture.

What happens if I use chisel chain or ‘ordinary’ cross cut chain to rip timber?

You can use it for one or two jobs but it is not recommended. You will find the vibration is a lot higher and the quality of the surface a lot rougher than if you used dedicated ripping chain. The harder the wood the more pf these issues make themselves felt.

Skip link and hyper skip link ripping chain – pros and cons

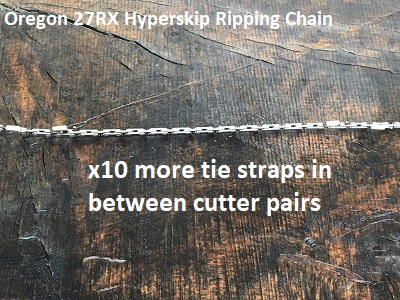

For longer bars (bars that are over 3 foot) you may consider using skip link chain on your chainsaw mill. Skip link chain has an extra tie strap between each cutter. This means there are less cutters taking ‘bites’ out of the wood, more space for chip waste to be expelled from the cut and less resistance on the chain so chain speed is kept up.

So why doesn’t everyone use it all the time? Because if you have a shorter bar and plenty of power you have less teeth cutting and so your cut will actually be slower and rougher than full comp chain. So it only starts coming into it’s own as bars become longer.

What chain sizes are available? There are now very few chains available in full skip that are micro chisel – you have Oregon 27AX which is full skip chain in 30 degree cross cut format. So you would have to alter the angle of this from 30 degrees to 10 degrees to make a skip link ripping chain.

NB – we now have Oregon 27RA which is full skip ripping chain.

The other option is Oregon 27RX. This is known as hyperskip ripping chain with x10 tie straps between each pair of cutting teeth! This comes pre sharpened to 10 degrees.

Lo pro ripping chain – pros and cons

Similar to skip link chain 3/8 lo pro ripping chain is not for everyone. However most chainsaw millers are always looking out for a longer bar to go on their existing chainsaw being that chainsaw is generally the most expensive part on a chainsaw milling system.

3/8 lo pro chain takes a very slightly thinner cut (around 15% to 20% thinner) than the larger standard 3/8 chain. This allows a smaller powerhead to drive a longer bar.

PROS

- Faster milling speeds

- Smaller kerf lost as sawdust

- Longer bars can be used on smaller chainsaws without straining the powerhead

CONS

- Lo pro ripping chain will suffer more chain stretch than standard 3/8 ripping chain

- Stay sharp ability is reduced due to smaller area doing the cutting

- Lo pro ripping chain is not as strong as standard 3/8 ripping chain – more chance of snapping particularly if abused

Who makes 3/8 lo pro ripping chains?

Oregon makes 91R – good for small chainsaws but not suitable on larger set ups.

Stihl makes 63PMX which is an excellent chain which gives superb performance straight out of the box and works well on larger set ups.

Granberg adapted 3/8 lo pro ripping chain is made from a Carlton chain and also provides good strong performance.

.

Differences between various manufacturers ripping chains

There are no concrete answers to this question. A little like which chainsaws are the best Stihl or Husqvarna. Suffice it to say if one was far better than the other then everyone would use the same chain. But they do not and really it is simply a case of which one you think works best for you.

.

Sharpening Technique and best practice

Within normal chainsaw use sharpening is one of the most important aspects of using a chainsaw. In chainsaw milling it becomes crucial. There is nothing new to be learned except to reinforce the basics of – consistent tooth length, consistent angle, correct chain shape, correct depth gauge setting.

Just getting one aspect wrong can slow your chainsaw milling to half the speed you could be going.

Quickly touching up a chain and chainsaw milling will cause poor results. Most people would benefit using some sort of fixed guide that controls tooth length. File size and where it is placed against the tooth controls the side plate angle and shape of the tooth. All chain sharpening principles remain the same – only the angle is different.

text or whatsapp us

text or whatsapp us  orders@chainsawbars.co.uk

orders@chainsawbars.co.uk

sign me up

sign me up basket

basket