Drive sprocket care

This is a very VITAL [notice the capitals – this means it is not a maybe I’ll check my drive sprocket – it means it like it reads it is VITAL] and often overlooked part of chainsaw maintenance. Drive sprockets match the pitch of the chain you are using. They should be changed every 2 to 3 chains. Try and identify which rim or sprocket you have.

Rim & sprocket

The rim and sprocket set up means it is easier and cheaper to change the rim which is the part that drives the chain [not that people do it – they don’t!]. These wear out faster than spur sprockets but they are cheaper. A rim needs replacing when it has worn 0.2mm.

Changing the rim

Changing the rim on Stihl chainsaws is straight forward. On chainsaws where the rim is inboard of the clutch, e.g. certain Husqvarnas chainsaws, you have to remove the clutch first. The picture opposite is when you should change the rim. Sadly the number of customers who use old knackered sprockets/rims and chains with a brand new bar – then complain that the bar has not lasted is growing! And what is even sadder is that when asked for pictures of said knackered sprocket/rim and chain – they are still none the wiser! CHECK AND REPLACE YOUR SPUR SPROCKET OR DRIVE RIM AND DO NOT USE YOUR OLD KNACKERED CHAINS ON A NEW BAR. Why ? because it won’t last and you have just ruined the most expensive part of the sprocket/bar/chain system. This is not just the homely handyman and the jobbing gardener who is guilty of this – it applies almost equally to long term professional users who should know better but don’t. CHECK AND CHANGE THE DRIVE RIM OR SPUR SPROCKET REGULARLY. THIS POINT WILL BE SHOUTED AND UNDERLINED AND IN BOLD UNTIL IT HAS SUNK IN!

Video advisory

Bar maintenance & rim change

on the Husqvarna 390XP

Spur sprockets

Spur sprockets drive the chain directly from the star shape teeth on the sprocket itself. When these have worn the whole sprocket must be replaced. These tend to wear slower than rims but are more expensive when you do come to replace them.

Outboard sprockets

Outboard of the clutch sprockets are easy to change, please see video.

Video advisory

Replacing an outboard drive

sprocket on a Stihl chainsaw

Inboard sprockets

Removing inboard sprockets are trickier as you need to remove the clutch assembly first.

This requires you to take the spark plug out and put a piston stopping tool in.

If you carry on using a worn sprocket it gets to the stage where it starts damaging the drive links, which in turn widen the bar groove, which then gives poor cutting, further accelerating the wear on all parts! For longer bars especially, this starts to get very expensive.

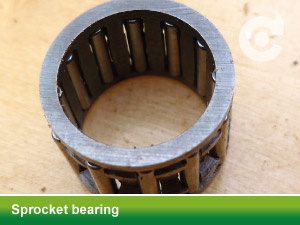

Sprocket bearings

Sometimes the bearing on a sprocket needs replacing. This is simply a case of removing the sprocket, sliding out the existing bearing and replacing it with a new one.

text or whatsapp us

text or whatsapp us  orders@chainsawbars.co.uk

orders@chainsawbars.co.uk

sign me up

sign me up basket

basket